A DVL enhancing autonomous navigation for ROV net inspections on fish farms

- User stories

Synopsis

Challenge

Inspecting nets at fish farms to check for gaps and reduce biofouling historically requires divers, an expensive and time-consuming process.

Solution

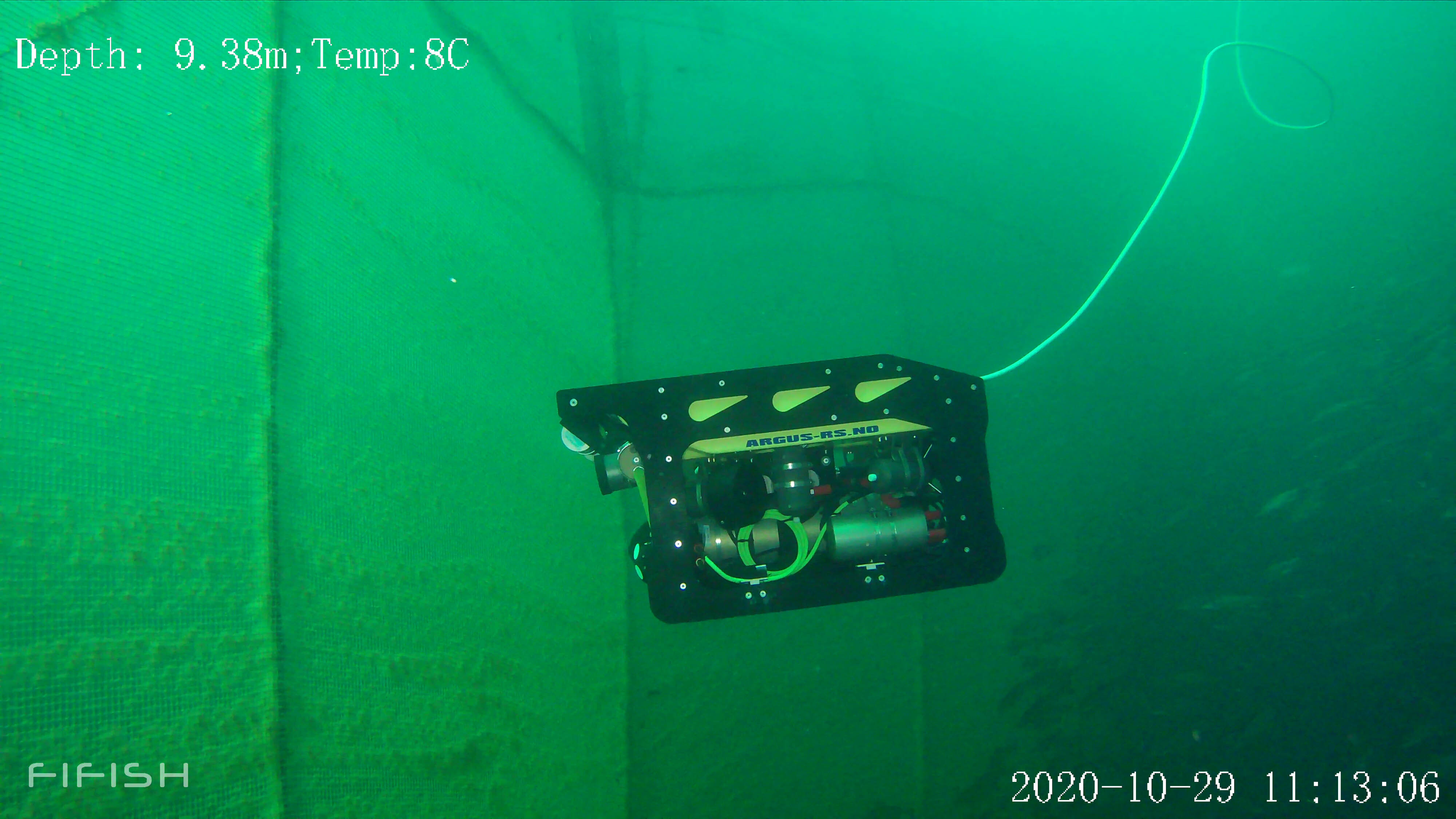

Norwegian research institute SINTEF led a project to develop an ROV with a high level of autonomous navigational capability to perform these net inspections, relying on a Nortek DVL to do the job.

Benefit

The DVL was able to precisely locate the vehicle with relation to the net, despite being an unusual material for a DVL to pick up on, allowing net inspections to be carried out using the vehicle.

Fish farming is a multi-million-dollar business that depends on careful maintenance of the giant cage nets to prevent stock from escaping through gaps, and to reduce biofouling on the nets since this can affect fish health.

Detailed inspections, which are crucial to this process, used to rely on sending divers down to check the nets. But that’s a cumbersome and time-consuming process, not least because there is a lot of netting to check – a fish farm cage is typically around 50 m across and 30 m deep.

Faster, efficient aquaculture cage net inspection with autonomous ROV navigation

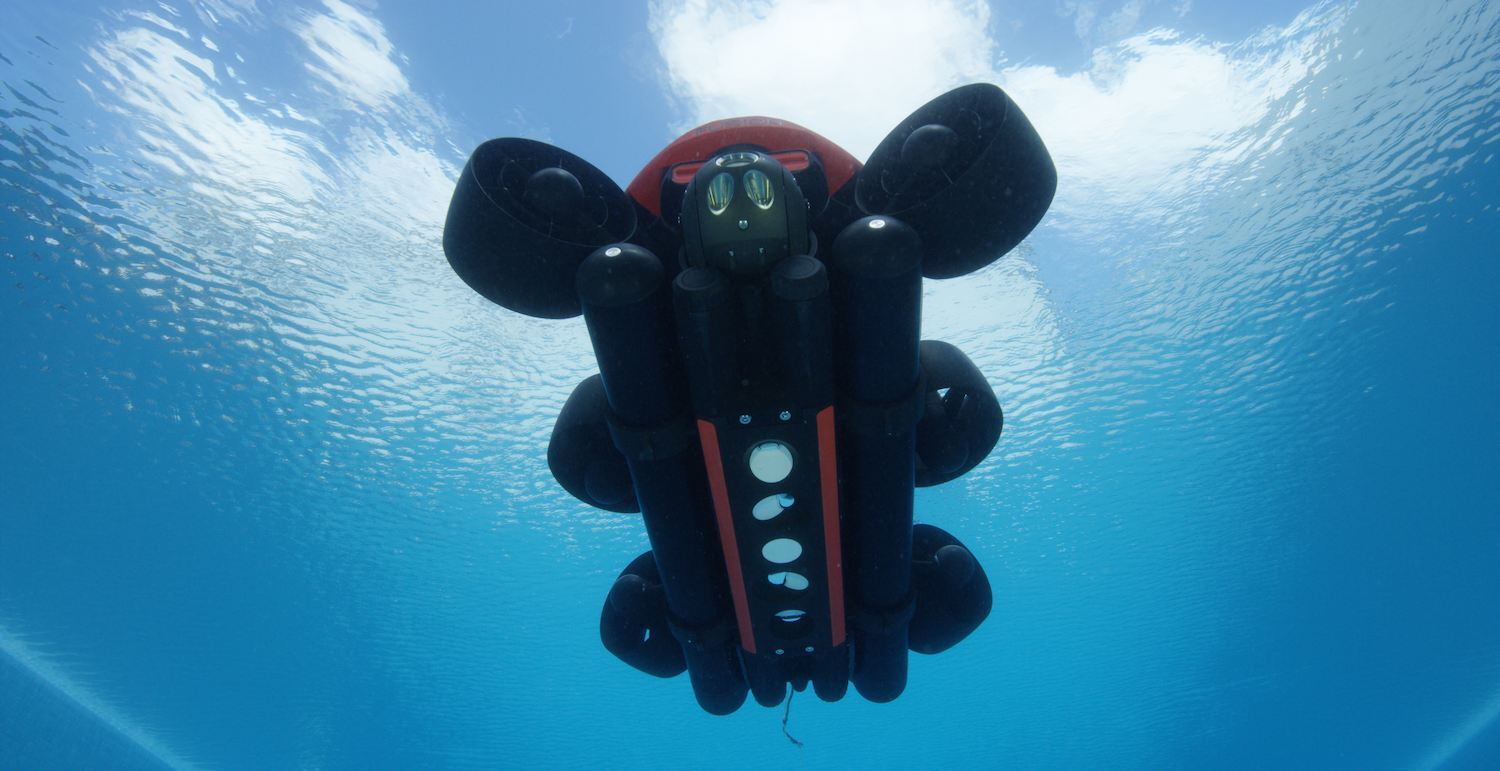

Today, remotely operated vehicles (ROVs) equipped with a camera and sensors do a lot of the inspection work. But these must be steered via a tether from the surface by a skilled pilot, whose attention is split between navigating the vehicle accurately around the edge of the cage – with control over little more than depth and heading – and doing the inspection itself.

If the operator could spend more time on the inspection, rather than navigation, the job could be done more quickly and efficiently. So, scientists from Norwegian research institute SINTEF hit on the idea of simplifying the task by developing a prototype inspection ROV with a high degree of autonomous navigational capability.

“If you can make the ROV ‘fly’ along the net autonomously, then the pilot can concentrate more on inspecting the quality of the net and deploying analytical equipment that is more complex to operate,” says Walter Caharija, a research scientist at SINTEF Ocean.

He led the project, known as Artifex (RCN project no. 256241), which built on the pioneering work of former SINTEF researcher Per Rundtop (MerdROV - RCN project no. 217541).

The team was able to carry out research in a fully operational commercial fish farm, known as the SINTEF ACE full-scale laboratory, which is located off Trondheim, the Norwegian city where the institute is based. Trondheim is a major center for the fish-farming industry.

Autonomous navigation possible with DVL able to detect even aquaculture cage nets

So how do you to get the vehicle to track the contours of the net from a fixed distance as it travels around the inside of the cage? This requires more than just knowing where the ROV is in the water. The vehicle also needs to know exactly where it is in relation to the net, which is constantly moving. That requires technology that can detect the net and accurately gauge the ROV’s distance from it, as well as calculating the vehicle’s speed along the net.

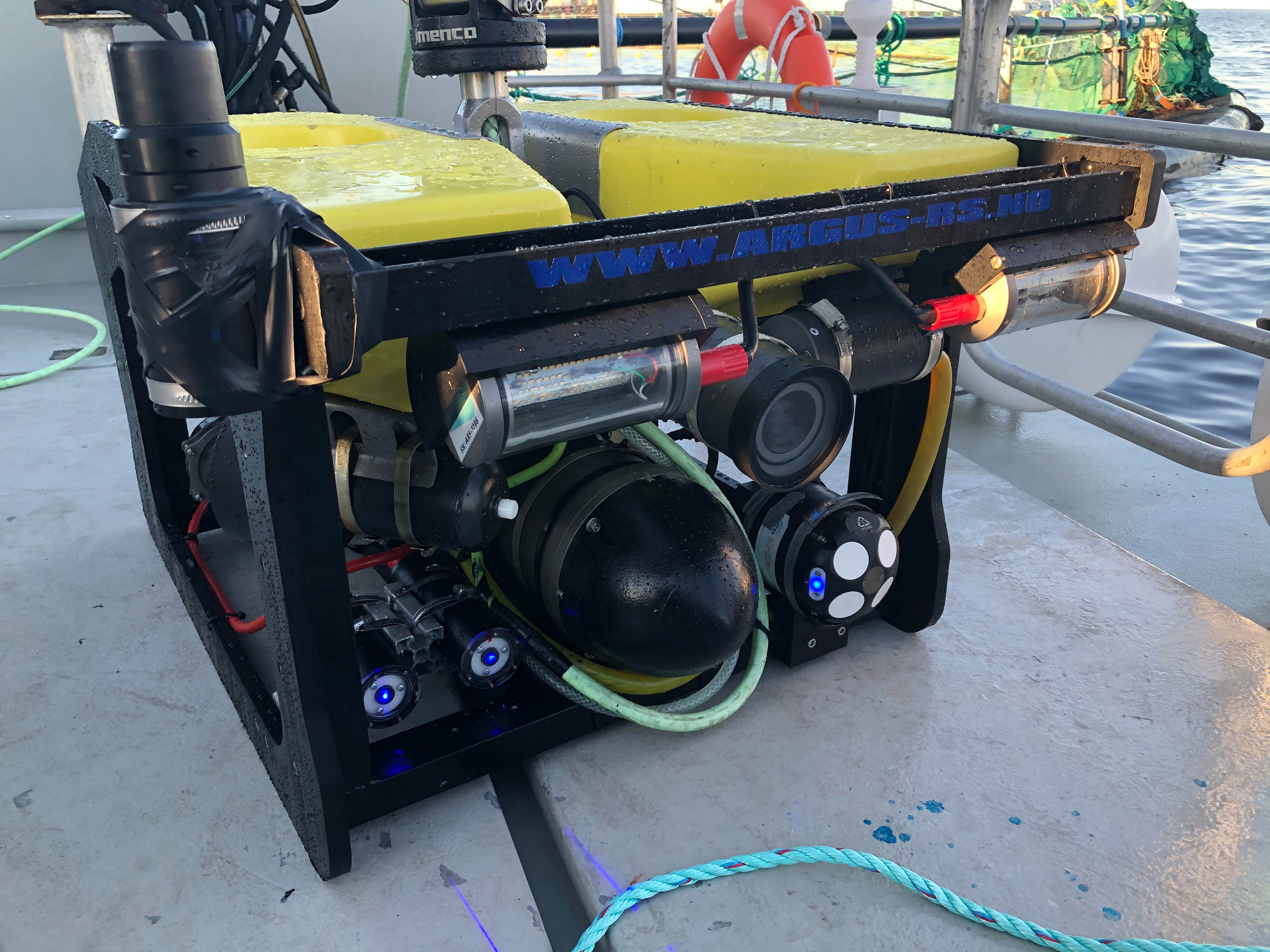

The team that carried out the early work thought using a Doppler velocity log (DVL), horizontally mounted on the frame of the ROV, could be the solution. But they weren’t sure whether a DVL would be capable of “locking on” consistently to a surface as ill-defined as a fish net.

DVLs measure velocity relative to a boundary – such as the bottom – by analyzing echoes bounced back from a hard surface. They are also able to measure distance from other types of surfaces accurately using a similar technique. However, these other types of surfaces tend to be a more clearly defined barrier, such as the seabed, rather than a mesh net.

The researchers got in touch with Nortek to see what was possible. Nortek said it was confident that its DVL1000 instrument would be able to “see” the net as it moved along the circumference of the cage – and that indeed turned out to be the case.

“We were able to help out at the beginning with signal interpretation to identify the nets, though the SINTEF team are highly skilled and understood how to use the DVL to get the best results,” says Tom Christian Mortensen, a field engineer at Nortek who supported the SINTEF team early on in the project.

“It was useful for us too, because, although we knew the DVL should be able to detect surfaces thinner than a fish cage net, it was good to prove it worked in practice,” he adds.

Using a package of navigational aids for operational success in aquaculture net inspection

In fact, the bigger challenge for the DVL operators wasn’t tracking the net, but dealing with noise reflected from fish swimming in the line of the DVL beams.

Signal scattering caused by air in fish bladders remains a challenge for all acoustic-based underwater instruments, even though some of the noise can be filtered out of results using algorithms. However, as the ROV’s main task is to patrol the inside of the cage at the relatively short distance of 1 to 3 m from the net, the problems caused by fish swimming between the vehicle and the net proved to be manageable.

“In a net cage there are, of course, thousands of fish, and if they intercept the beams then you lose the track. But when the ROV is close to the net, typically the fish stay out of the path,” says Herman Biørn Amundesen from the SINTEF team.

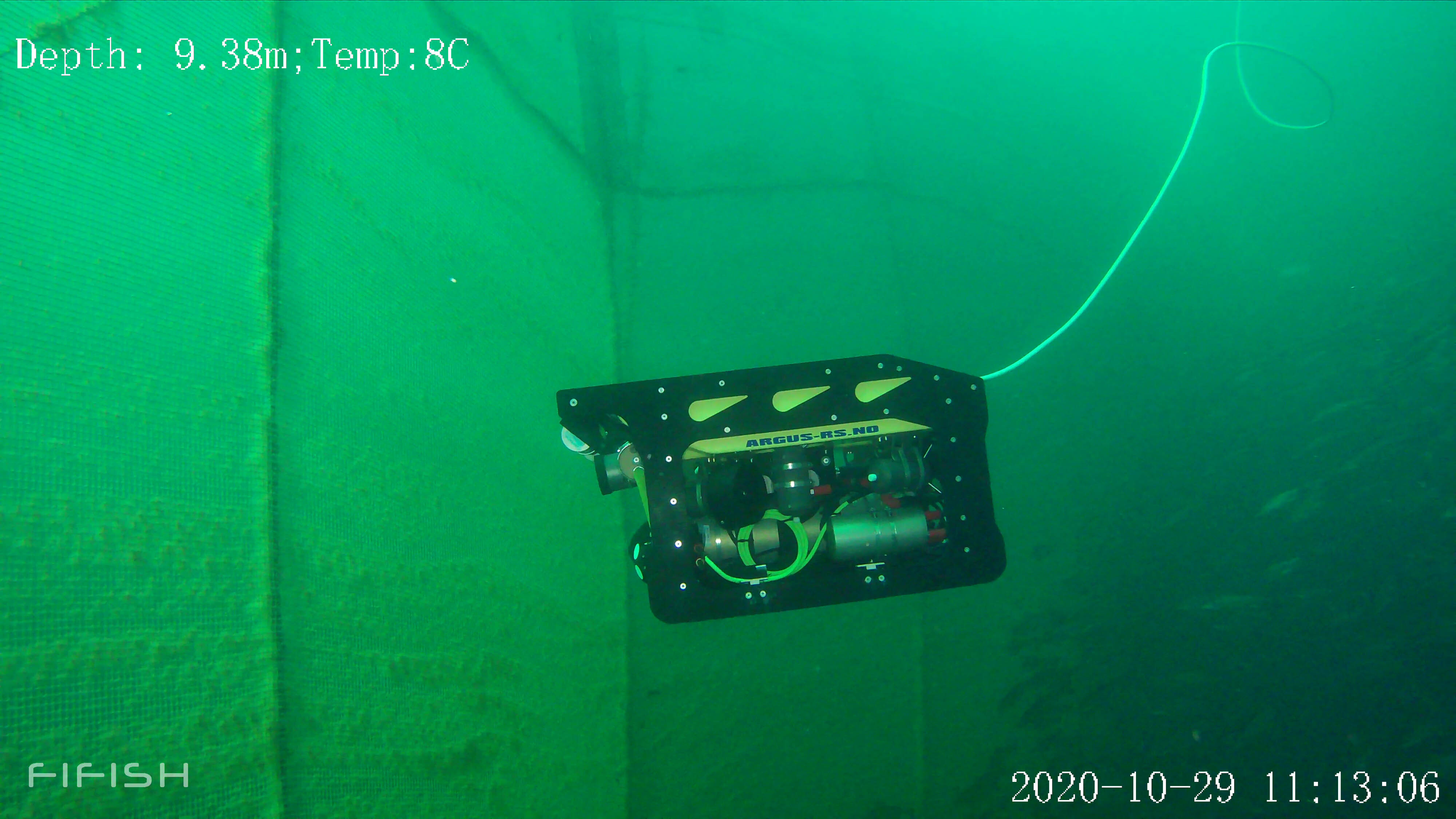

The DVL is part of a package of navigational aids, which Walter Caharija describes as a “sensor fusion”. Ultra-short baseline acoustic positioning (USBL), compass readings, a laser system and the on-board camera all contribute location data. But, in terms of maintaining distance from the cage net, it is the DVL that does the work.

Development in-house makes the DVL “very reliable” for ROVs used in aquaculture

Caharija says the Nortek DVL has done the job well. The team used laser measurements to verify those from the DVL and they confirmed its accuracy.

“We’ve been satisfied with the instrument’s performance. In the early tests we got it to lock on to the net to provide distance and velocity measurement without any major problems, helped by hints from Nortek, and it has proven to be very reliable in measuring distance from the net,” he says.

He is also happy with the level of support provided by Nortek. “Nortek was very helpful in setting up the DVL. We have had good communication with the Nortek team in Oslo, and now in their new Trondheim office. I definitely hope to keep on developing this relationship with future projects,” he says. “Nortek is one of the most innovative companies when it comes to subsea technology, especially the DVL. They do a lot of development in-house that makes the instruments very reliable,” he adds.

Testing an aquaculture ROV in deeper, rougher waters

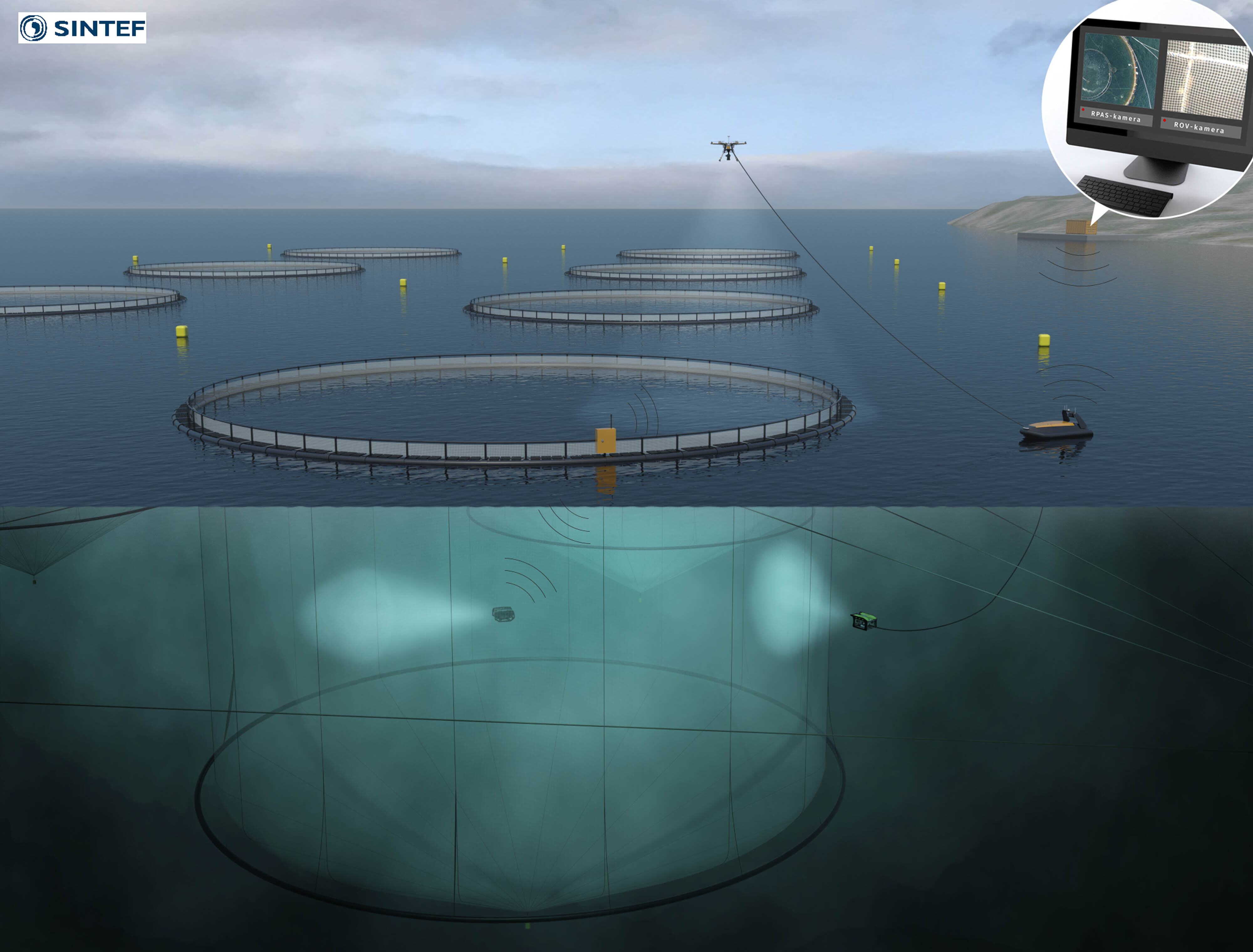

Artifex and its successor projects are part of a drive with much wider ambitions. They could pave the way for completely unmanned fish farms, with monitoring and repair controlled remotely by personnel based on land, and repairs carried out by ROVs, rather than divers, as is the case now.

The Artifex team also aims to fit the ROV with a robotic arm to carry out net repairs, while the project partners are developing an unmanned surface vessel (USV) to which an ROV could be tethered, along with a drone to assist inspections.

Moving fish farms further offshore is a growing trend as farmers seek to meet growing global demand for fish. So the next step for the researchers is to move away from the relative calm of near-shore fish farms to test the ROV in deeper, rougher waters.

The SINTEF team are doing this as part of the Exposed project (RCN CRI, project no. 237790/O30), a joint venture between academic researchers, aquaculture companies and technology firms to develop new, low-cost techniques for many aspects of fish farming in more exposed locations.

In calmer waters close to shore, a vessel can be attached to the net, making interaction with the ROV to which it is tethered relatively straightforward. However, in more exposed locations with rougher seas, it may not be safe to attach the vessel to the net, making the process of keeping it on station above the ROV a lot more complicated.

"In those conditions, tasks such as the launch and recovery of the ROV can be as big a challenge as actually operating it underwater," says Herman Biørn Amundesen.

In practice, these added complications mean ROV missions in exposed fish farms are more vulnerable to being cut short by a closing weather window. This, in turn, makes any extra time that can be devoted to net inspection an even more precious commodity, accentuating the benefit of autonomous navigation using the DVL. Time is money for aquaculture companies – the more you can get done in a shorter time, the lower the cost.

Developing new control systems for aquaculture autonomous navigation and maneuvering

SINTEF is also working on a related project, CageReporter (RCN project no. 296476). Its main objective is to develop sensor systems for high-quality data acquisition from within fish-farming cages using autonomous and non-tethered vehicles, and the transmission of the data acquired to land. The project has shown that it is possible to mount a plethora of sensors on board ROVs to simultaneously analyze fish health and water quality with high precision and transmit the data efficiently back to base.

New control systems for autonomous navigation and maneuvering in the unstructured and dynamic environment of a fish cage are also being developed in the project, which is industry-backed and involves several research institutions.

These projects are providing the groundwork for a revolution in fish farming. They should help the industry to produce fish for expanding world markets at low cost in a wider range of environments, and with rapid access to more detailed information on fish health, fish welfare, water quality and cage integrity.