How to combat biofouling and extend your ADCP deployment

- Nortek Wiki

1. What is biofouling?

Biofouling refers to the accumulation of marine organisms on man-made underwater objects, for example the underside of ships, underwater structures and oceanographic equipment such as current profilers and wave measurement sensors. The biofouling process starts with the adsorption of organic molecules to a surface, which leads to the attachment of further layers of microorganisms, such as bacteria or algae.

This biofilm may in turn attract larger organisms, including marine invertebrates such as barnacles, mussels and sponges, and then crabs, shrimps, snails and other mobile organisms.

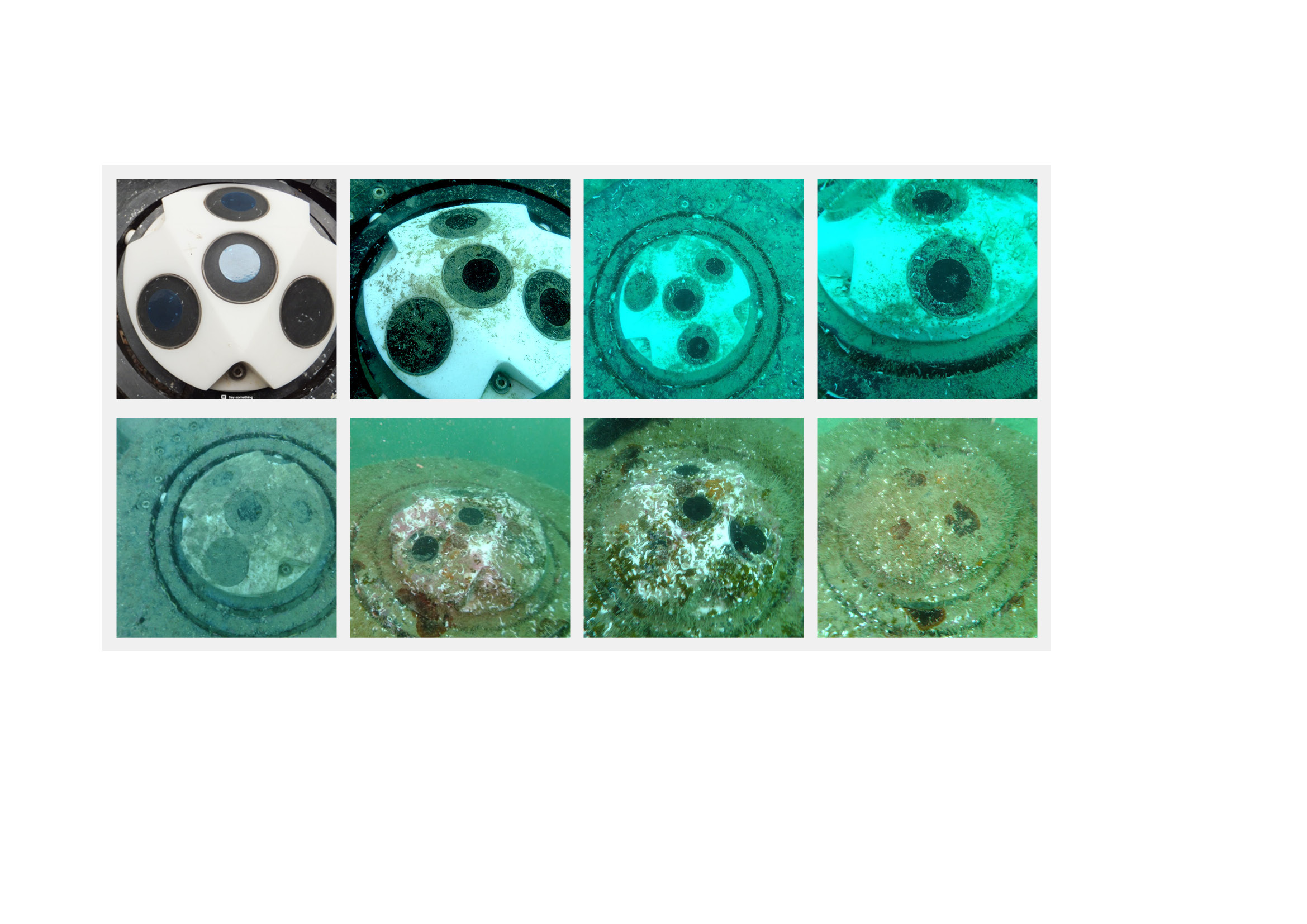

In this image you can see an AWAC ADCP where a part of the instrument’s transducers had been covered with antifouling patches before deployment in the sea. The area covered with the antifouling patches is clear, while the parts of the transducer not covered by these patches are now covered with biofouling.

The problem of biofouling tends to be most pronounced in:

- warmer, tropical waters

- still, low-energy environments

- shallow applications (light- and temperature-dependent)

- areas with higher nutrient input

2. Why is biofouling a problem when measuring waves and currents?

Biofouling is a significant issue because it limits the deployment time and increases the cost of a measurement campaign.

Even though the current velocity is not normally affected, the profiling range of an ADCP will decrease as the build-up on the transducer elements increases. Also, in some conditions, mussels and barnacles etc. can grow on or close to the instrument. In long-term deployments, rubber connectors may eventually be destroyed as a result.

Thus, biofouling can interfere with the instrument’s ability to collect correct data, even before its power and/or data capacity has been reached. The costs of the instruments, batteries, deployment and recovery, travel (boat time etc.) and other factors add up to significant sums.

Therefore, it makes sense to do everything possible to combat biofouling to ensure that the deployment can be extended for as long as possible, while ensuring that the data collected is trustworthy and of high quality.

3. Reducing biofouling: Some methods we don’t recommend – and a good solution

There are a few methods in use to reduce biofouling. Some are “classical” methods and have been used for many decades. Other methods are new and have only been in use over the last few years. First, let’s review a few commonly used methods that we don’t really recommend, namely toxic paints, zinc oxide and Vaseline.

3.1 Using paints and homespun methods to reduce biofouling on ADCPs

Ships and outboard engines etc. are usually painted to protect against biofouling. While some of these paints can be quite effective in hindering growth on oceanographic instrumentation, some are no longer legal for environmental reasons, some can destroy the instrument and some reduce the effective profiling range of ADCPs.

- The most effective paints contained organotin compounds that acted as a biocide. These compounds, such as TBT, are now banned in antifouling paint by the International Maritime Organization’s International Convention on the Control of Harmful Anti-fouling Systems on Ships.

Other antifouling paints, containing copper, have also been sold, but these are not recommended for use with ADCPs for three reasons: (1) the paints can be damaging to benthic ecosystems and water quality in general; (2) some of the paints include large flakes of copper that can diffuse the acoustic radiation patterns; and (3) other paints have been found to be acidic and can damage the polyurethane surface used in most transducer designs.

For ADCPs, two homespun antifouling methods have also been used.

- The first involves applying zinc oxide paste (sold as skin protection for babies) to the area around the transducers (see photo below). This paste contains a zinc-based biocide that is poisonous to the small marine organisms that want to colonize the substrate, thereby reducing the amount of organic material able to attach itself to the instrument. Note that zinc paste will wash away, especially in higher-energy environments.

- The other creative method is to mix Vaseline with cayenne pepper and smear it onto the device to discourage organisms from attaching themselves to the transducers.

Both these methods have only anecdotal success, and we are not aware of any tests having been carried out to systematically measure the increase in deployment time.

3.2 Using a protective film/coating to reduce biofouling on ADCPs

A more recent – and more sophisticated – solution is the application of a protective film or coating. There are at least two providers at present, and they use competing approaches to the problem of application.

Nitto (Japan) has developed adhesive antifouling stickers that users can attach directly to the transducers. This allows the equipment to function normally, while providing a transparent, silicone-based surface to which it is difficult for microorganisms to adhere. This is an antifouling solution experts at Nortek can recommend with confidence.

The Nitto stickers are particularly effective where water movement helps to wash the organisms away from the surface of the ADCP transducers, and these stickers can be peeled off after use.

An ADCP before deployment, where the transducers have been covered with antifouling stickers.

The stickers are made of silicone resin, polyester film and acrylic adhesive. As the stickers do not rely on biocides or poisons to combat biofouling, they are considered to be better for the environment than many paints or coatings.

Nortek has worked with multiple customers to test the Nitto patches, and the results suggest that the stickers produce good results even in areas where biofouling problems are severe. The stickers are fairly simple to apply and remove. Antifouling stickers for many of Nortek’s ADCPs can be purchased in the Nortek web store.

Another product that can control biofouling on ADCPs is a non-toxic coating made by Severn Marine Technology (USA). This uses what the company refers to as the ClearSignal® Biofouling control system, where the entire sensor or vehicle is covered following a special process. ClearSignal® is a clear, non-toxic coating that resists biofouling as a result of its non-stick properties. The product is a permanent coating that is designed to last the lifespan of the platform or instrument it is protecting. To apply ClearSignal® to your instrument or sensor, contact Severn Marine directly.

See this support article to learn more about how to clean instruments and how to prevent biofouling.

The same two ADCPs shown earlier in this article. The transducers protected by stickers (the ADCP to the right) are relatively clear, while those covered with zinc paste (the ADCP to the left) are covered in organic material/biofouling.