Explaining online measurement of oceanographic data

- Perspectives

What it is online measurement of oceanographic data?

An online measurement is real-time telemetry (or transmission) of sensor data to either a secondary telemetry system (i.e. satellite or GSM modem) or directly to a PC for real-time or near real-time display or storage.

There are many benefits of getting online data. One is being able to use the data for real time processing or for display immediately after the data are collected. For example, processing of data collected in real time allows for weather forecasting, daily operations and public-safety applications. Another benefit of transferring the data from the sensor in online mode is that users will have a second copy of the data should something happen to the sensor during normal operation, such as ice damage or damage from a fisherman. There is great value in using such an online system because in most cases the data being collected are much more valuable than the instrument itself. In other words, you will not be leaving valuable uncollected data deep in the ocean.

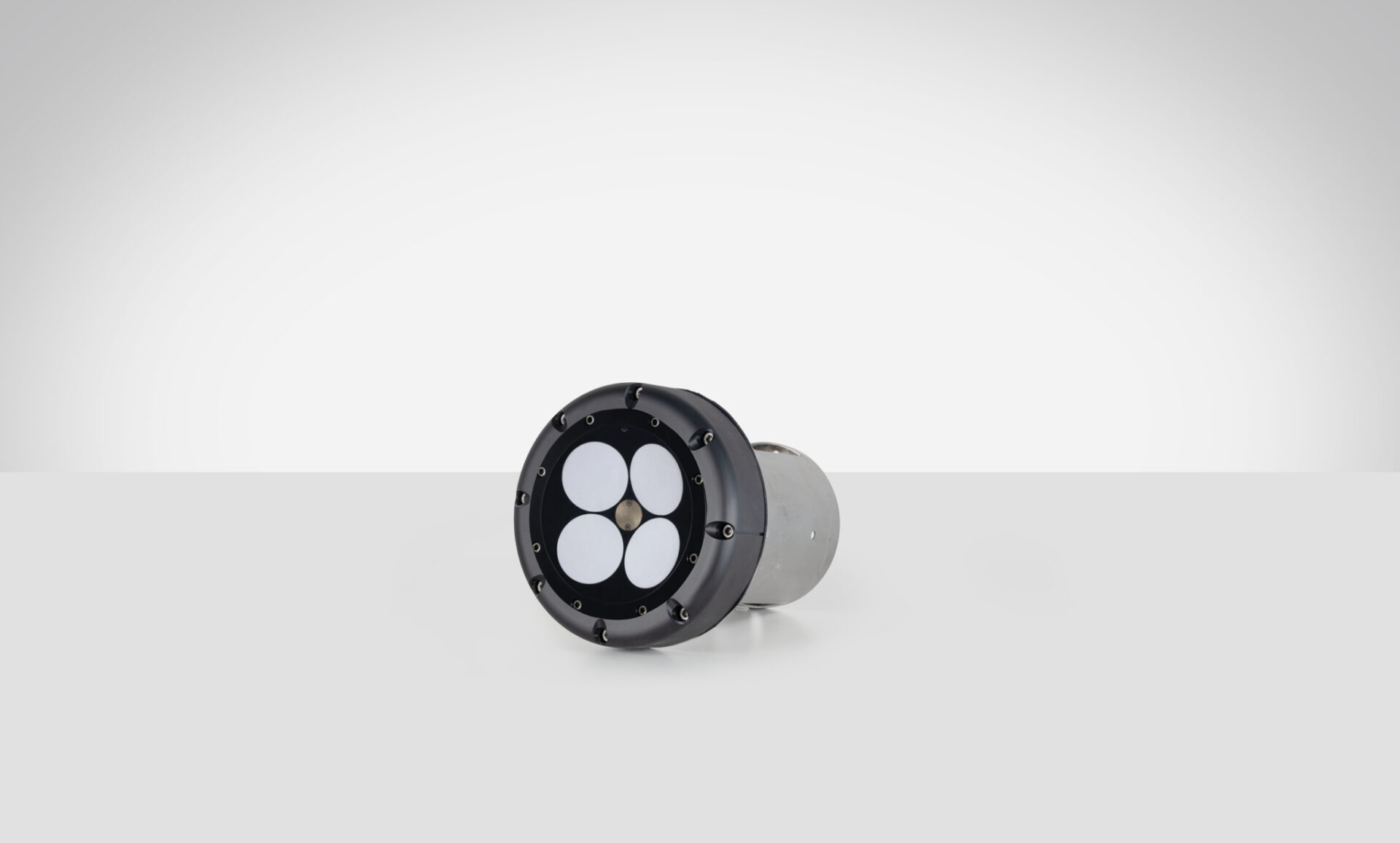

The Nortek 400 kHz 2D Profiler.

How online measurement of oceanographic data works

A cable is connected to the Nortek sensor and the sensor is configured to transfer the collected data as the sensor operates. These data can be either raw unprocessed data or in some cases subsets or processed data packets. Subsets or processed data packets are ideal when the telemetry link has a lower data transfer rate – such as an underwater acoustic modem. The cable into the Nortek sensor can be either an Ethernet connection, an RS-232 or RS-422 cable connection, or in some cases an analog connection.

Keep these potential challenges in mind

It can be challenging to operate an online telemetry system. If subsea cables are used those cables can be subject to vandalism, wave damage, fish bites, marine growth and storm damage – as well as a host of other factors that can damage cables. When using long cables, it can also be a challenge to provide sufficient power for instruments to operate. Properly armored cables with service loops are recommended to avoid cable breakage, wave damage and other similar hazards. (A service loop is a section of cable intentionally left loose to aid in serviceability.)

It can also be very beneficial to use pre-molded cables that have been pressure tested to ensure that water does not enter the online system via connectors or an underwater connection between two cables.

Seek assistance from a qualified electrical engineer to solve issues related to power requirements, cable types and telemetry protocol. This is often overlooked! In some cases, telemetry protocols can also create a challenge when the selected protocol does not support the cable length, or when it picks up electrical noise when long cables are used. This electrical noise can come from nearby AC power lines, wireless transmitters or other sources of electrical noise.

Make sure to test before deployment

After selection of a proper power supply, telemetry protocol, and cable specification it is highly recommended to fully test all equipment as it would be used when fully deployed.

Testing it for a period of days, not only briefly, is preferable. While the sensor may not be collecting useful data during this testing, configuration issues may become evident and can be resolved before the system is deployed. Troubleshooting and modifications when the system is deployed can turn out to be very difficult and expensive. Issues such as instruments not being set to the correct protocol, improper cable wiring, cable damage or other issues are much easier to fix when in a laboratory environment.

How Nortek online measurement technology meets end user needs

Although online systems can have some challenges to overcome, Nortek offers a number of solutions to help solve these challenges.

Nortek offers reliable and well-engineered cabled online systems that can operate from 10 meters up to several kilometers. With power regulation, protocol management and cable designs all pre-engineered and offered as standard products, these solutions can make a difficult design process very easy.

The 400 kHz 2D Profiler was mounted on a semi-submerged dock piling (the dock’s “leg”) and connected to the port operators via an online cable.